Description

Product Display:

Structural Analysis

Technical Parameters

| Item No.: | ZB2000C | ZB3000B | ZB4000B | ZB6000B |

| Laser Wavelength | 1080nm | |||

| Laser Power | 2000W | 3000W | 4000W | 6000W |

| Beam Quality | <1.4m² | |||

| Adjustable Range of Laser Power | 1-100 | |||

| Laser Light Output Mode | CW/PWM | |||

| Power Stability | ≦3% | |||

| Laser Focus | F=180mm | |||

| Repeatability | ±0.01mm | |||

| CCD Positioning Accuracy | 0.01mm(Option) | |||

| Welding Ranging | X-Axis: 800mm/1000mm | |||

| Y-Axis: 600mm/800mm | ||||

| Z-Axis: 400mm | ||||

| Working Temperature | 5-45℃ | |||

| Cooling System | Exterior Water Cooling | |||

| Power Consumption | 3.5KW | 5.5KW | 8KW | 10KW |

| Power Supply | 380V/50Hz | |||

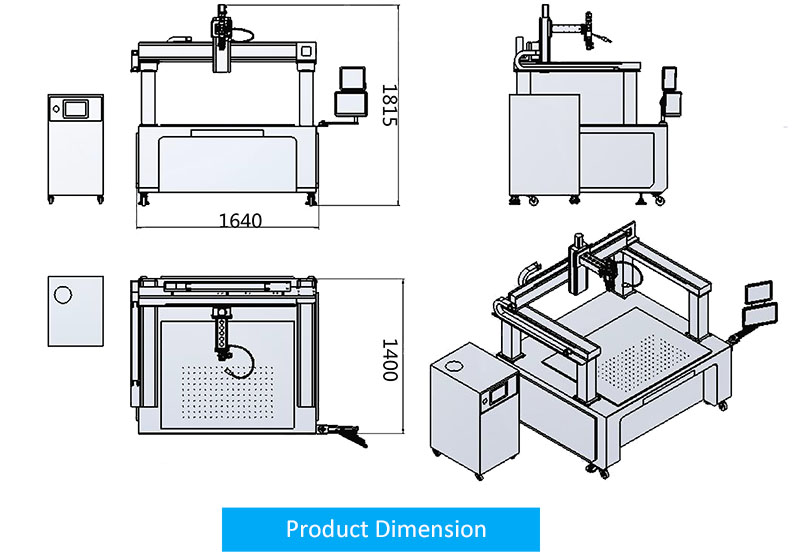

| Size (L*W*H) | 1200mm*1400mm*2000mm/1400mm*1600mm*2000mm | |||

Working Principle and Characteristics

- Adopt with idea light sources:Continuous fiber laser device could switch to continuous or pulse working mode;

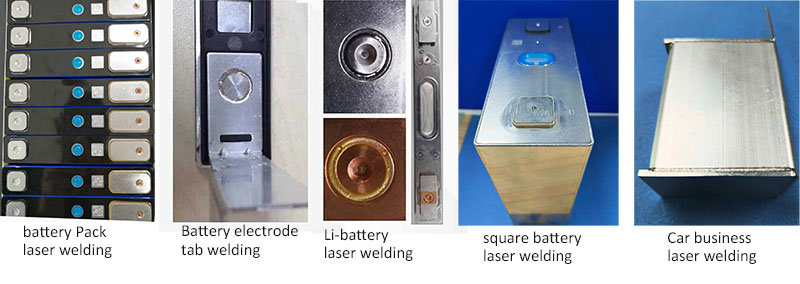

- It could realize many idea welding effect,such as Spot welding,butt welding,stitch welding;

- The professional welding software could realize light source,machine,power and software optimized combination through extensional I/O port with full automation;

- The 4 axis gantry with high precision working mode could realize big item welding with stable working environment;

- The high power scanning mirror with higher precision could improve the welding efficiency;

- It could optimize the laser output light spot by changing the setup of light path to realize idea welding effect;

Scope of Application

Reviews

There are no reviews yet.