Program Overview

E-cars not only make big influence at consuming market,but also bring innovations at car manufacturing.Battery,motor,ECU are core three parts of E-cars takes up high percentage of the total costs,vital for car endurance and safety,needless to stress the importance of car battery.

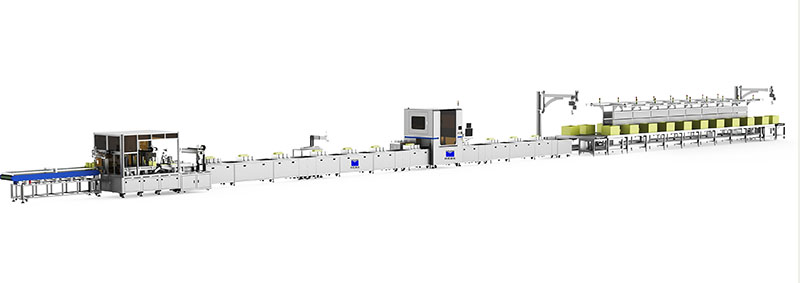

In the process of battery assembling,many steps needs to be done by welding which includes Anti-exploding Valve sealing part welding,battery tab welding,soft connection welding,safety part spot welding,battery cover sealing part welding,mould and PACK part welding,covering the whole procedures of car battery assembling.

The traditional welding inevitably leave issues like over-welding or less welding,blowhole,surface cracks which could cause possible corrosion and loose.On the other hand,even if the welding job is done it still needs to be re-polished and cost more.So for how to solve such issue is the crucial point for the whole industry.

Laser welding technician will customize the clients’ needs from battery material,shape,thickness,traction,etc. to choose suitable laser head and welding parameter.The laser welding could focus the energy,high welding efficiency advantages and more applied to auto battery production and car manufacturing.