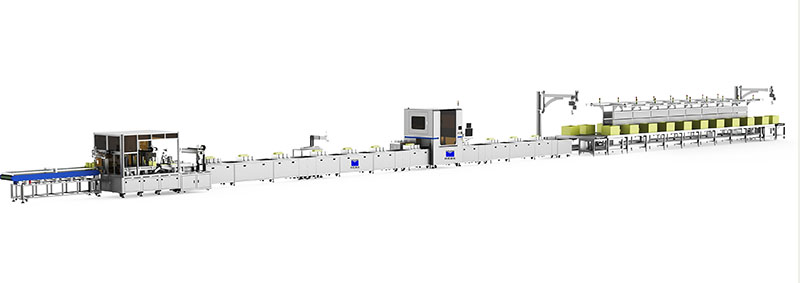

Packaging Industry

Food safety is most concerning issue to public,and food packaging is closely related with safety.

The food package is most important part of product.Apart from keeping fresh,storing food,it also could acquired food originality,food composite,food warranty,storage conditions,etc.Due to the transportation,handling,etc.facts,the oil printing could be easily erased. Some lawbreakers would erase the expiring production date and print with new date for resale.It will have bad effect of people’s health and break the market principles.For laser marking technique perfectly solve the such issue.

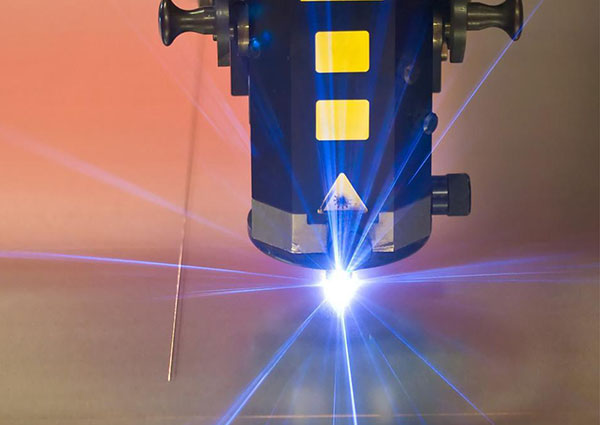

Laser marking

Laser marking is applying high density energy to certain part and make material surface for vaporization and color changing by chemical reaction.It’s permanent marking way with precise marking,high speed,clear marking and no pollution,etc,characteristic.All the info should be marked on the package which is hard to modify and fake,and at same time could build data system for us to track,check product status.For the laser marking info like production date,food origin,etc.,are clear, eye-catching,and permanently,even if it was erased,and the package would be also damaged.It is great to protect the public’s rights.

Laser drawing

When the customers buy fried food,the sealing part is not so good,and food are easily popped out.And also sometimes the sealing part is too tight,it will be difficult to tear it part.It will be a big headache thing to customers.For laser marking machine could easily do line marking,it would be easy to tear but also keep the completion of the bag.

In other way,if the material adds aluminum foil or other metal layers,it would stop the laser beam to damage other material.With such help,the laser could do package location,drawing and drilling easily.For laser line marking or drilling could do great protection of package integrity,at same time have great ventilation and moisture function to the package.

For the package laser marking or cutting application is not only for food industry,but also for cosmetic package,medicine package,jewellery package,gifts & crafts packages,etc.

Leather Industry

Leather is rather excellent material for being used for many centuries.Leather is proved to be the great material apply to laser cutting and engraving.

With the development of new technology,leather products are used more and more widely.It plays inevitable role to our daily life,such as clothes,shoes,bag,wallet,slippers,hat,watchband,cushion,car wheelchair and steering wheel,etc.Leather products are creating unlimited commercial value.

The high energy and power CO2 laser could cut and engrave leather fast,efficient,and continuously.The laser cutting machine adapts with digitization and automatic technology,providing laser hollowing,laser engraving and cutting service for leather industry.

Compared to the traditional cutting technology,CO2 laser cutting machine got obvious advantages.Its got low cost,low consuming,no requirement of machine part.It is easy to operate and maintain,continuously working with high precision and fast speed.

Leather laser cutting

Leather industry is experiencing new technology revolution,which solves the issue of slow speed and hard to composing compared to the traditional industry.It is easy to operate, only input shape and size into software,and no need mould and others.

CO2 laser cutting machine could perfectly cut leather,synthetic Leather,PU leather,man-made leather,suede,napped leather, superfine fibre,etc.

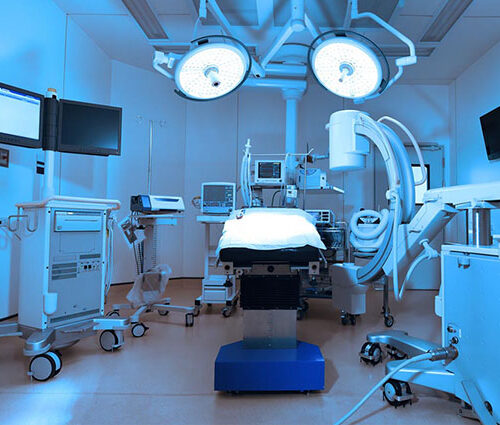

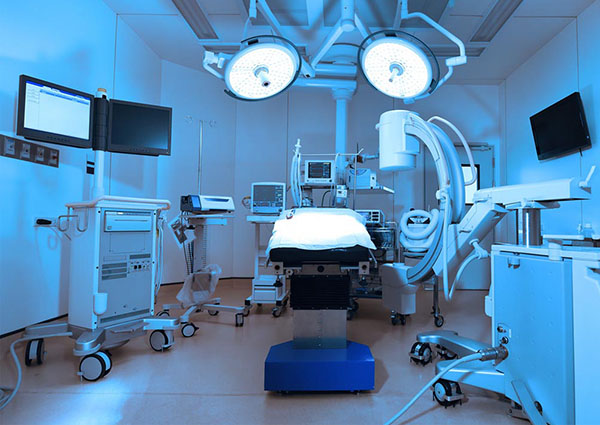

Medical Equipment Industry

Program Overview

Medical industry is the biggest concerns for all the countries,especially due to covid.The medical equipment is getting more and more cutting edge.There are lots of inner components are quite precise.For laser technology are mostly applied to medical equipment manufacturing process which includes laser marking,laser welding,laser cutting,laser micro-machining,etc.

Typical Application:

Medical equipment laser marking application

Medical business are closely related to everyone’s life and health,so anti-counterfeiting is most important chain to protect consumers’ safety.Such as,The FDA issued strict regulation that all the medical equipments must have only UDI in compulsory, it means that all the medicines and medical equipment should make the serial number for future tracing.

Our most commonly seen medical equipment,such as bone screws,pacemaker,auditory Implantation device and endoscope device,etc. are all applied with laser marking.The laser marking could permanently mark with company info and product info,it is corrosion proof and traceable.It is DPM way for laser marking.

Medical equipment laser welding application:

For the medical equipment inner components are very precise and laser welding is widely applied to medical equipment and perfect meet the needs.

Laser welding is widely applied to medium precise medical equipment by spot welding,slit bonding and sealing.It could do welding job with less than 1mm components and parts,such as pacemaker,operation knife,endoscope and battery,etc.

Medical equipment structure is precise and complicated with strict requirement of safety,cleanliness,tightness,etc.Compared to other technique,the laser welding technology wouldn’t cause any welding Slags and no need any extra material for gluing which could be done in clean environment.

Medical equipment laser cutting application:

Medical equipment plays vital role in people’s life’s safety.High precision laser cutting machine could cut tiny parts of metal or plastic material.Most of these parts are applied to human heart,brain or eye stent(Nitinol and Co-Cr alloy material),conduit,cardiac valves and polymer tubes.

Green Energy Power Industry

Program Overview

E-cars not only make big influence at consuming market,but also bring innovations at car manufacturing.Battery,motor,ECU are core three parts of E-cars takes up high percentage of the total costs,vital for car endurance and safety,needless to stress the importance of car battery.

In the process of battery assembling,many steps needs to be done by welding which includes Anti-exploding Valve sealing part welding,battery tab welding,soft connection welding,safety part spot welding,battery cover sealing part welding,mould and PACK part welding,covering the whole procedures of car battery assembling.

The traditional welding inevitably leave issues like over-welding or less welding,blowhole,surface cracks which could cause possible corrosion and loose.On the other hand,even if the welding job is done it still needs to be re-polished and cost more.So for how to solve such issue is the crucial point for the whole industry.

Laser welding technician will customize the clients’ needs from battery material,shape,thickness,traction,etc. to choose suitable laser head and welding parameter.The laser welding could focus the energy,high welding efficiency advantages and more applied to auto battery production and car manufacturing.

3C Electronic Industry

Program Overview

3C refers to computer,communication,consumer electronics as abbreviation.It got short life cycle,fast cost dropping and flexible global influence.With the steps of digital era,3C is becoming one of strongest new technology industry with the fastest developing and changing.

With the fasting development of 3C industry, 3C is working toward high integration,high precision,the inner components are getting smaller,higher precision and more integration.For smaller,thinner and more portable are designers’ ultimate pursuit. It brings with new material and new technique,and laser is new technique for 3C industry.

The traditional printing,stamping,cnc machining techniques are no longer could meet the tight budget control,tiny inner structure of components.The laser could have less heating area,more precise machining,faster speed that are easily to realize new techniques which traditional way couldn’t.All the new material and new techniques couldn’t live without automated laser marking,laser welding,laser engraving,laser drilling,etc.

Typical Application

3C laser marking and engraving technique:

Laser marking could apply to white oil,green oil,black oil,etc. and copper surface to do laser marking or engraving.It could make the material,production process,production time,manufacturer,tracing info to QR code and mark or engrave onto 3C products surface for further tracing and management.

The characters that laser engraved are high precision,clear and delicate outlook.It reduces chemical and noise pollution.

3C electronic industry laser welding application:

Laser welding is to apply laser beam into welding material,and melt the welding parts to joint together.The laser welding is process of laser and material mutual working which relates to reflection,absorption,heating,fusing,vaporization,etc.It divided into Laser heat conduction welding and penetration fusion welding.

With the electronic products are getting smaller and high expectation from end users,it causes higher welding techniques requirement.For laser welding machine is high quality,high precision,low deformation,high efficiency and high speed welding device,it becomes to be most important tool for metal material machining and production,widely apply to 3C industry.

3C electronic laser cutting technique:

Laser cutting machine could work with multi-metal material and non-metal material for high precision cutting and micropore machining.it got high precision,fast speed,limited heating effect,etc advantages,especially for hard density, high brittleness,and High-melting-point material with precision cutting.Compared to the tradition cutting,it got significant advantages.

Laser cutting also got wide application at FPC cutting areas.FPC is made of multiple layers, with circuitry located both internally and externally. In comparison, a flat flexible FPC is characterized by a flat design, allowing for smaller profiles.It is mostly applied to mobile phone,laptop,tablet,PDA,digital camera,LCM products,etc.

Apart from that,laser cutting are commonly applied to blue diamond glass screen cutting,camera protection screen cutting,mobile phone home button cutting,FPC flexible board cutting and mobile phone earphone drilling,etc.

Hardware And Mould Industry

Program Overview

Hardwares plays great role at our life.with the development of economy and division of Labor in Society,the hard-wares are gradually getting richer and more options.

For current metal hardware are divided by applications with 3 types:as daily commodities,as hand tools to produce and assistance daily life;as building or objects connection,fasten and part of equipment.For metal material hardware needs to be processed by extrusion forging,machining,surface processing and etc.The surface processing purpose is for anti corrosion and being good outlook.Most non-metal hardware are made by mould or forging making with light weight characteristic.

Hardware machining with laser device could greatly reduce the new products machining and manufacturing period and mould investment.It could improve the worker’s processing efficiency and avoid non-necessary machining procedure.Meanwhile it could process complicated machining parts,improve the accuracy,reduce the delivery time and more productive.

Typical Application

Hardware products with laser cutting application

With laser technology applied to different areas,such as at our kitchen cabinet and cooking wares.For most of the hardware are with stainless steel and Aluminum alloy material which is perfect for applying with laser cutting machine.The laser cutting device is applied to cut raw material with high precision,high performance and flexibility at kitchen hardware application.Meantime,laser welding machine could do different metal parts binding.It got big advantage for mass production with less deformation,high efficiency,wide application.

Laser cutting could avoid saw blade cutting with hairline burrs’ issue and once for all efficiency.The cutting way is very accurate and seldom with reprocess or waste.The speed is 3-5 times faster than saw blade cutting.All the laser cutting could be customized by customers.Just simply input relative data of machining parts could realize high accuracy and precision,good looking laser cutting effect.

Hardware products laser marking application:

Most of hardware products need to be marked with key info like product name,barcode,serial number,instruction,or production date,etc.Compared to traditional printing,hand made engraving,electric processing and tool engraving,laser marking machine could eliminate the burr parts fast,character or logo printing,anti-counterfeiting marking,product serial number marking,product number marking and barcode marking etc.Laser marking got advantage of flexiblity,high conversion efficiency(PCE)of diode,and easy to maintain.It is mostly applied to high standard of high surface finish,details and depth areas.It focuses the light beam to the metal material with instant heating to leave permanent marks.For iron,copper, stainless steel and Aluminum alloy,etc are widely applied to laser marking.

Hardware products laser welding application:

Hardware industry laser welding are greatly applied to phone parts welding,stainless steel screw welding,and small hardware parts welding.The advantage of laser welding is energy centralized,zero-pollution,small spot welding.Due to the welding machine got high precision,fast in speed,the raw material non-distortion after welding,etc. Characteristic,more and more industries are applied with such technology.

Hardware mould industry killing points:

- The process is complicated and lots of uncertainty of machining,and big demanding of processing equipment fixer and gigs;

- 2.Most are finished or half-finished products.The commonly are multi batches with less quantity, mostly are customized,and the process are frequently modified;

- Compared to the other industry,most of the worker in hardware industry are less educated and needs lots of labor involved.So it is inevitable to come up quality issues with poor operation standard.

The advantages of applying laser to Hardware mould industry:

The traditional machine cutting and argon arc welding are facing low efficiency and poor working performance which are no longer meet the modern hardware mould industry needs.So the high precision laser automatic welding and cutting system came to the market.Compared to the knife cutting machine,the laser machine adapts contact-less heating way with high energy focus,tiny facula,small heating area got better performance.

The laser cutting machine could easily do customization without complicated knife design and making,more free to do random design and cutting.It could save the material and improve the efficiency.Compared to the traditional cutting,the laser cutting is 8-20 times faster.

Take laser cutting machine as example,the price is 1/10 of the traditional knife cutting machine with same work efficiency.

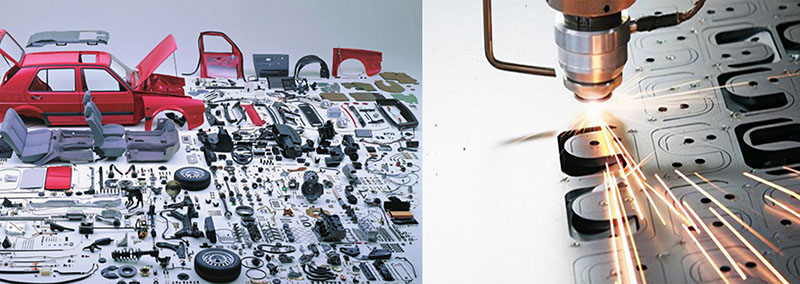

Auto Parts Industry

Program Overview

The car industry competition is facing new revolutionary and competition is even more fierce globally.Especially for E-cars development which boost the application of laser machines for car manufacturing.

For hundreds of thousands of parts of car processing are mostly made by laser machine.It related to car roof welding,side door welding,floor welding,back cover welding,etc.For laser machine could be the new weapon for auto industry upgrade.

Typical Application

Auto parts Laser cutting application:

Laser cutting is one of the most commonly way of laser processing.For laser cutting could be divided into laser vaporized cutting,laser melting cutting,laser oxygen cutting,laser scribing and control.Compared to the traditional machining process,laser cutting got high cutting quality,less cutting range,small heated zone,sharp cutting edge,fast cutting speed and flexible cutting shape,and applied to bigger range of materials and more advantages.For big cover parts of cars cutting are made by 3D laser cutting machine which is easily to be programmed to routine operation,easy to install,and reduce the production time.

The laser cutting technology application includes:auto parts,car covers,car door,trunk,car roof and etc.For most developed countries,50%~70% car pasts are accomplished by laser machines.For laser cutting is main applications which costs is 80% of the traditional cutting.

Auto parts laser marking application:

For auto parts production,ID confirmation is basic needs for quality tracking and be called in which is made by marking way.Laser marking utilizes high power density laser focus on certain parts that could vaporize or color chemistry change and leave the marks.Laser marking is contactless process could mark at any shape material without affecting the shape or inner force.For auto parts are adapted with varieties of material,such as matal,plastic,galss,porcelain,wood or leather,etc,to marking at the surface.

Auto parts laser welding application:

Laser welding takes the advantage of high power density,less shape changing and heating area,easy to be automated and no further processing,etc which is most important part of car manufacturing.For the body of a car could include hundred of thousand of parts,it is crucial to join all parts together.For laser welding could weld different thickness,type,grade of metal material together,it improves the production efficiency and quality,at same time it increases the flexibility of car design and material selection.

Lighting Fixtures And Accessories Business

Program Overview

Lamp is an indispensable part of lighting tools to our daily life. The lamp is far more than lighting purpose,but even more for house decoration.With the big demand of lamp high quality and great taste from consumers ,the light industry keeps on innovating and improving.Therefore,the technics and craftwork of whole lamp processing is even stricter.For the laser technology could perfect realize laser marking,cutting and welding.

For medium or lower power laser machine are widely applied to regular material or metal material processing. Currently laser cutting and marking machines take up 80% of medium or lower power laser machine market coverage

Laser processing is flexible applied to 2D or 3D areas .There is no need to move around during the whole laser processing.As long as you keep the laser device and material into moving mode without any blocked areas,it could save extra matching and simplify the process.The laser machine operated by the computer all the way which is no need to operate separately,mould setup or reset processing routine.So for simple click and play which greatly reduce long preparation for operators.The laser machines got fast working speed,reduce the processing time and improve the productivity.

Typical Application

Laser cutting Application in light industry:

For light industry,mostly the technics and craftwork are complicated due to big application of crystal and metal materials especially for round or flat metal materials.The traditional processing is by CNC punching process and turns out the finished products with lots of defects.If it is small mount by making moulds could cost even more money.If there is big amount of mass production which could be easily to outdated by new fashion.

The laser cutting machine could cut different shapes in different tubes as well flat metal material or cutting tube at side.It is equipped with high power vacuum could get rid of leftovers easily without re-cleaning.The laser cutting machine could apply to stainless steel,aluminum plate,copper,brass and more high reflective material.It perfect meets with small amount customized needs of home decoration.

Laser marking Application in light industry:

The traditional silk printing method on led fixers are easily to be erased and faked.For laser marking not only clear and beautiful at outlook but also not easy to be erased,equipped with rotational platform could save labour cost.

Laser marking machine could engrave on metal material or part of non-metal material.The laser light beam is very slim could meet more precision and smoothness application.It could work 24 hours without any stop.There is no radiation,no consuming material,and adopts to metal material and plastic material for laser engraving.

Laser welding Application in light industry:

The traditional TIG welding is unstable and easily to be deformed with quite many defects.When it is finished welding,it still needs further polishing/The whole process is quite complicated with lots of costs which is disadvantage for mass production.The laser welding machine could be operated by industrial control panel to do contactless welding,fast in speed with good looking and flat seaming part.It doesn’t need too much process when it is done.The welding quality is good with limited heat affection area and deformed part.

The fast development of laser industry boosts the emerge of laser welding technology.The laser welding uses high power laser pulse to heat specified area,and the material melt to achieve welding purpose.For handheld laser welding machine could apply to different stainless steel light fixer,steel craftwork parts,zinc-plated light fixer,etc.