Program Overview

The car industry competition is facing new revolutionary and competition is even more fierce globally.Especially for E-cars development which boost the application of laser machines for car manufacturing.

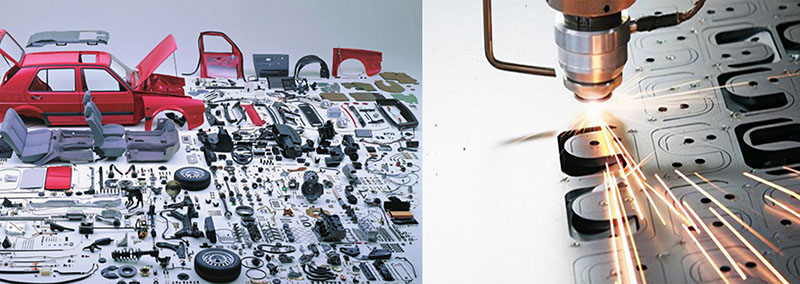

For hundreds of thousands of parts of car processing are mostly made by laser machine.It related to car roof welding,side door welding,floor welding,back cover welding,etc.For laser machine could be the new weapon for auto industry upgrade.

Typical Application

Auto parts Laser cutting application:

Laser cutting is one of the most commonly way of laser processing.For laser cutting could be divided into laser vaporized cutting,laser melting cutting,laser oxygen cutting,laser scribing and control.Compared to the traditional machining process,laser cutting got high cutting quality,less cutting range,small heated zone,sharp cutting edge,fast cutting speed and flexible cutting shape,and applied to bigger range of materials and more advantages.For big cover parts of cars cutting are made by 3D laser cutting machine which is easily to be programmed to routine operation,easy to install,and reduce the production time.

The laser cutting technology application includes:auto parts,car covers,car door,trunk,car roof and etc.For most developed countries,50%~70% car pasts are accomplished by laser machines.For laser cutting is main applications which costs is 80% of the traditional cutting.

Auto parts laser marking application:

For auto parts production,ID confirmation is basic needs for quality tracking and be called in which is made by marking way.Laser marking utilizes high power density laser focus on certain parts that could vaporize or color chemistry change and leave the marks.Laser marking is contactless process could mark at any shape material without affecting the shape or inner force.For auto parts are adapted with varieties of material,such as matal,plastic,galss,porcelain,wood or leather,etc,to marking at the surface.

Auto parts laser welding application:

Laser welding takes the advantage of high power density,less shape changing and heating area,easy to be automated and no further processing,etc which is most important part of car manufacturing.For the body of a car could include hundred of thousand of parts,it is crucial to join all parts together.For laser welding could weld different thickness,type,grade of metal material together,it improves the production efficiency and quality,at same time it increases the flexibility of car design and material selection.